The under-glaze and over-glaze techniques are two core ceramic decoration methods. Their differences in process, pigment properties, and decorative effects are significant. Below is a detailed explanation of the process, key points, and comparative analysis.

I. Under-glaze Decoration Technique Process and Analysis

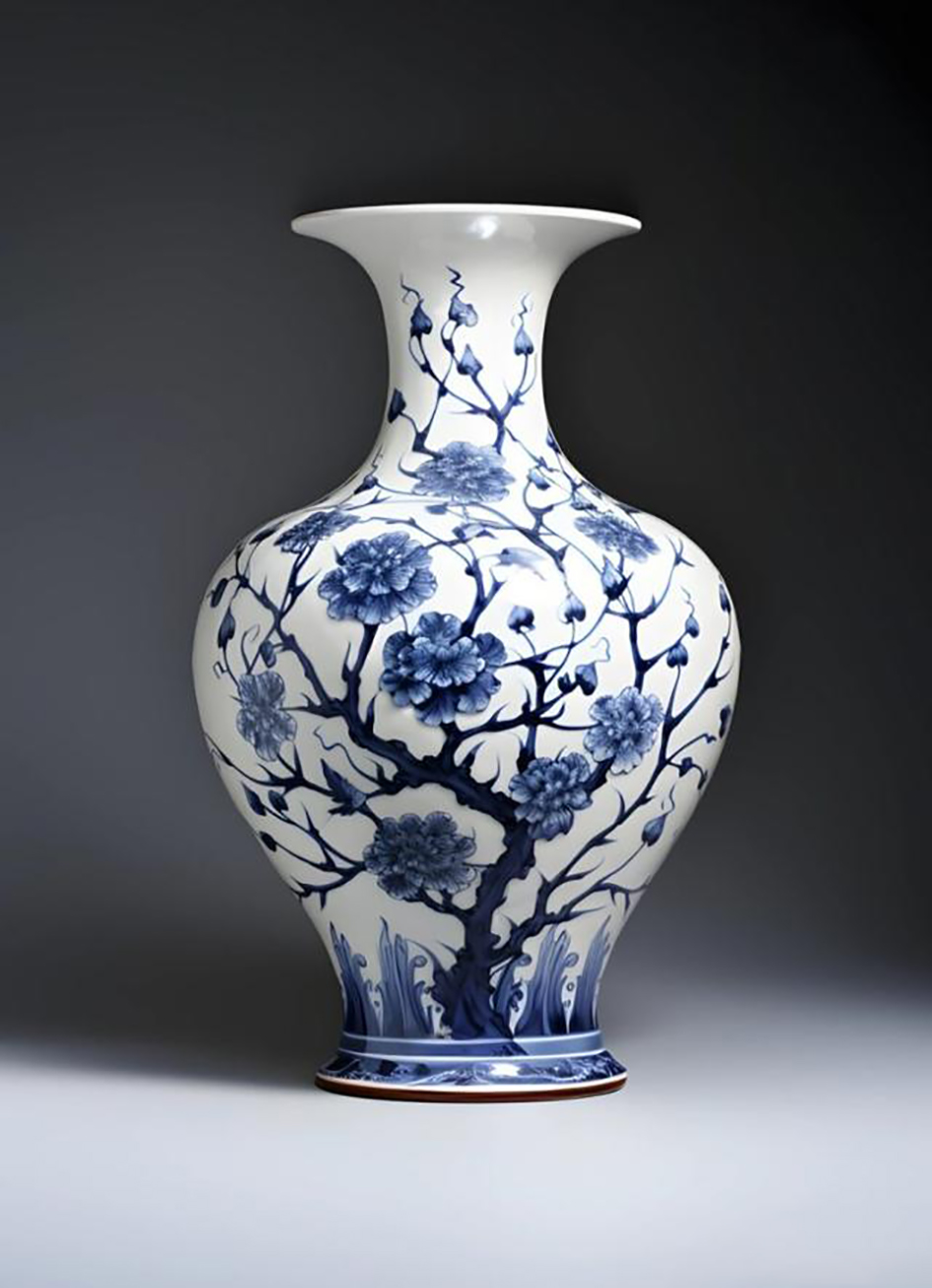

Technique Process (Example: Blue and White Porcelain)

Preparation of the Body

After forming the body (by wheel throwing, slip casting, etc.), the clay is allowed to dry to about 10% moisture content naturally and then undergoes bisque firing at approximately 800°C to strengthen the body and make it easier for subsequent painting.

After bisque firing, smooth the body surface to remove any burrs, ensuring that the paint adheres evenly.

Under-glaze Painting

Pigment Preparation: Primarily mineral-based pigments (e.g., cobalt, iron oxide, and copper oxide) are mixed with water or plant gum (e.g., peach gum). The pigments need to be fine to avoid clogging the brushes.

Painting Techniques: The pattern is directly outlined and filled in on the bisque-fired body. It is essential to control the pressure of brushstrokes, as the glaze applied afterward may cause slight blurring of the pigment. Therefore, the lines must be planned to withstand the glaze firing.

Typical Case: In blue and white porcelain, cobalt is used to paint the design, and it remains stable in blue color after firing, unaffected by the glaze.

Glazing Process

Glazing methods depend on the object’s shape: small pieces are dipped in glaze, while larger pieces are sprayed or brushed with glaze. The glaze layer is typically 0.5-1 mm thick. It may run if it is too thick; if it is too thin, it won’t cover effectively.

The glaze must match the clay body’s expansion coefficient to avoid cracking during firing. Common under-glaze includes feldspathic glazes and calcareous glazes.

High-Temperature Firing

The firing temperature typically ranges from 1200-1350°C, using either an oxidizing flame or a reducing flame (e.g., blue and white porcelain is often fired in a reducing flame to make the cobalt appear more vibrant).

The heating curve must be carefully controlled: a slow ramp-up to 600°C to remove moisture and a prolonged high-temperature stage to melt the glaze and achieve vitrification. Rapid cooling can cause cracks in the glaze.

Key Points Analysis

Pigment High-Temperature Durability: Under-glaze pigments must endure temperatures over 1200°C. The metal oxides in the pigments (e.g., cobalt, iron, copper) interact with the glaze layer at high temperatures to form stable colored glazes.

Pigment and Glaze Combination: After melting, the glaze should completely cover the pigment layer, forming a three-layer structure (pigment - glaze - clay body). The fluidity and melting point of the glaze must match the pigments.

Decorative Effect: The glaze covers under-glaze patterns, making the surface smooth and durable. These are suitable for daily use ceramics (e.g., bowls, plates), but the color may change slightly due to high temperatures, requiring pre-firing tests to calibrate the color balance.

II. Over-glaze Decoration Technique Process and Analysis

Technique Process (Example: Famille Verte Porcelain)

Base Porcelain Preparation

First, the glazed porcelain body is fired at 1200–1300°C. The surface of the porcelain is fully vitrified, hard, and smooth, forming the base for over-glaze decoration.

Over-glaze Painting

Pigment Preparation: The pigments mix metal oxides (such as gold, silver, iron, and antimony) with fluxes (e.g., red lead, borax). The flux lowers the melting point of the pigments (about 700-900°C), allowing them to melt and adhere to the glaze at lower temperatures.

Color Mixing and Painting: The pigments are mixed with glue (such as glycerin or peach gum) and then applied to the glazed surface to create detailed patterns. The colors are bright and rich (e.g., red, green, yellow). As the pigments do not need to withstand high temperatures, a wider range of pigments can be used.

Decal Technique: In modern techniques, over-glaze decal decoration often uses decal paper, where the design is printed on decal paper and then transferred to the porcelain using water or heat, improving efficiency.

Low-Temperature Decal Firing

The piece is then refired at a lower temperature (700-900°C) for 30-60 minutes, allowing the flux in the pigments to melt and form a mechanical or weak chemical adhesion with the glaze.

The decal firing temperature must be carefully controlled (about 5-10°C/min) to avoid cracking or color fading due to differences in thermal expansion between the porcelain body and the pigments.

Key Points Analysis

Pigment Adhesion: The flux holds over-glaze pigments in place after firing, but the adhesion is weaker than under-glaze, making the surface more susceptible to wear. These are not suitable for frequent wipes.

Color Stability: Over-glaze pigments, particularly those used at low temperatures, are more vivid (e.g., colors such as pink and purple, which tend to decompose at high temperatures, can only be applied using overglaze decoration), but they may fade with long-term exposure to acidic or alkaline substances. Therefore, they should not be used for items that hold corrosive liquids.

Technique Flexibility: Over-glaze techniques allow for additions and modifications to the design after the base firing, making them ideal for intricate patterns and personalized creations. Intricate decorative techniques such as famille rose and enamel painting all fall under the category of over-glaze decoration.

III. Notes for Techniques

Under-glaze Decoration: Test the compatibility of pigments with the glaze beforehand to avoid color bleeding or glaze bubbling during firing. Ensure an even application of glaze to prevent bare spots or uneven colors.

Over-glaze Decoration: Ensure the decal firing temperature within the glaze firing temperature to prevent deformation of the glaze surface. Avoid applying a thick layer of pigment, as it may crack during cooling. Lead-containing pigments must be used in controlled amounts and avoided for tableware (modern techniques have increasingly adopted lead-free pigments).